Parker SMARTFLUXX Series Nitrogen Membrane Modules

SmartFluxx design optimizes highest nitrogen capacity and lowest feed-air consumption, keeping the modules the smallest available on the market. SmartFluxx provides nitrogen gas of 90% to 99,5% equivalent nitrogen purity.

Parker hollow-fibre membrane modules produce nitrogen gas from compressed air to offer a cost effective, reliable and safe solution to on site nitrogen gas generation. SmartFluxx nitrogen membrane modules are manufactured with a life-expectancy of over 10 years, with no performance decrease over time due to fibre ageing during the manufacturing process.

Call us TODAY at 727-835-0649 or

Toll Free at 800-761-4298

Get A Free Quote!

More nitrogen per fibre is produced from Parker hollow fibre membranes than any other in the world, together with the lowest module pressure drop, meaning fewer membranes are needed per nitrogen system. Gas is generated via a low pressure standard industrial compressor results in operational energy savings.

The correct purity is available instantly as there is no need to heat-up the membrane to open the polymer structure, consequently further reducing the energy consumption, resulting in reduced CO2 emissions.

SmartFluxx offers flexible mounting solutions offer a small system footprint. With no serviceable parts, Smartfluxx operates maintenance free.

Sizing and Model Selection

For more information or a detailed discussion about your specific requirements please contact us at 727-835-0649 or Toll Free at 800-761-4298.

*Scroll to the right to see entire chart on mobile.

Dimensions in (mm) and weight lbs (kg)

For dimensions and weight please see the specific model product sheets below:

- SMARTFLUXX SA604 Product Brochure

- SMARTFLUXX SA708 Product Brochure

- SMARTFLUXX SA1508 Product Brochure

- SMARTFLUXX SA15020 Product Brochure

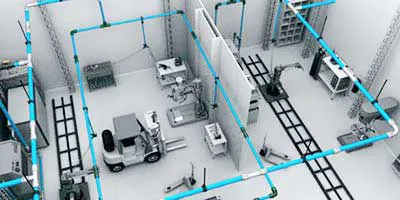

Also Available from mdi: Parker Transair Aluminum Pipe and Fittings for Compressed Air

Transair aluminum pipe is the ideal system for compressed air, vacuum, and inert gas applications. It offers significant savings on installation, maintenance and operating costs when compared to traditional compressed air piping systems. Its removable and interchangeable components allow users to easily modify production layouts or execute process changes within minutes. It's the only product with true push-to-connect fittings, eliminating the need to thread, solder or glue pipe. Its unique sealing technology guarantees Transair to be leak-free.

Continue...

Click for Larger View

Click for Larger View