Parker Hiross Hyperfilter Series

Compressed Air Filter

The Parker Hiross Hyperfilter coalescing, dry particulate and oil vapor removal filters have been specifically designed to remove dirt, oil, moisture and other impurities, offering a comprehensive range of compressed air filters covering all industrial needs.

Die cast aluminium and fabricated carbon steel coalescing, dry particulate and oil vapor removal compressed air filters.

Call us TODAY at 727-835-0649 or

Toll Free at 800-761-4298

Get A Free Quote!

Compressed air incorporates a high concentration of dirt, oil, moisture and other impurities. Failure to remove these contaminants will lead to escalating maintenance costs, lengthy downtimes and damaged finished goods.

Hyperfilter coalescing, dry particulate and oil vapor removal filters have been specifically designed to prevent these undesired effects, offering a comprehensive range of compressed air filters covering all industrial needs.

Available in 5 filter grades: Coarse pre-filter, general purpose and high efficiency coalescing filters, dry particulate filter and oil vapor removal filter.

Features & Benefits of Parker Hiross Hyperfilter Compressed Air Filters:

• Protects tools and downstream equipment • Increases efficiency, reduces downtimes • Significantly reduces maintenance costs • Full range of models and filtration grades for all industrial applications

Accessories & Options

• Kit for installation in series of two or more filters

• Wall mounting kit

• Counter flange kit (for flanged models)

• Element supervision indicator

• Differential pressure gauge

• Flanged models can be supplied in stainless steel for aggressive ambient conditions

Sizing and Selection

To ensure quoted air purity specification is met, more than one filtration grade may be required.

Important Note: For quoted air purity performance, compressed air filters must be sized correctly for minimum operating pressure and maximum inlet flow rate using the correction factors found in the Product Information Sheet.

For more information or a detailed discussion about your specific requirements please contact us at 727-835-0649 or Toll Free at 800-761-4298.

*Scroll to the right to see entire chart on mobile.

*Scroll to the right to see entire chart on mobile.

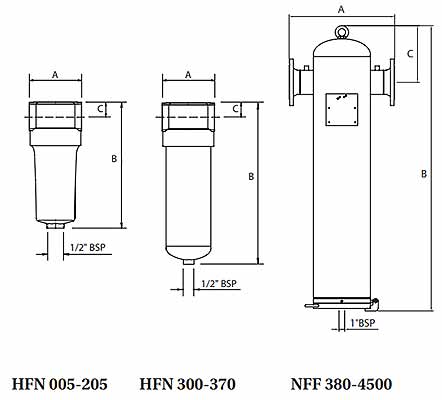

NFF Models Dimensions (mm) and weight (kg)

*Scroll to the right to see entire chart on mobile.

Also Available from mdi: Parker Transair Aluminum Pipe and Fittings for Compressed Air

Transair aluminum pipe is the ideal system for compressed air, vacuum, and inert gas applications. It offers significant savings on installation, maintenance and operating costs when compared to traditional compressed air piping systems. Its removable and interchangeable components allow users to easily modify production layouts or execute process changes within minutes. It's the only product with true push-to-connect fittings, eliminating the need to thread, solder or glue pipe. Its unique sealing technology guarantees Transair to be leak-free.

Continue...

Click for Larger View

Click for Larger View