Parker PTW Series Regenerative Desiccant Air Dryers

Parker PTW Series Heatless Regenerative Desiccant Dryers are ideal for critical, high quality, oil free air treatment applications where very dry air is required. These dryers typically provide pressure dew points of -40°F (-40°C) down to -100°F (-73°C) pressure dew point (pdp).

Beneficially, a pressure dew point of -15°F (-26°C) or better will not only prevent corrosion, but will also inhibit microorganisms within the compressed air system Heatless adsorption or desiccant dryers remove moisture by passing air over a regenerative adsorbent material which strips moisture from the air. This process is known as Pressure Swing Adsorption.

Call us TODAY at 727-835-0649 or

Toll Free at 800-761-4298

Get A Free Quote!

Dryer of this type are extremely efficient and provide typical pressure dew points of -40°F (-40°C) or -100°F (-73°C) pdp. This means that for water vapor to condensate into a liquid, the air temperature would have to drop below -40°F (-40°C) to -100°F (-73°C) respectively. Note that the actual air temperature after an adsorption dryer is not the same as it's dew point. The desiccant material is contained in two separate but identical pressure vessels commonly referred to as "twin" towers. As the saturated compressed air flows up through the "on line" tower, its moisture content adheres to the surface of the desiccant. The dry compressed air is then discharged from the chamber into the distribution system. An onboard solid state controller automatically cycles the flow of compressed air between the towers. While the "on line" tower is drying, the "off line" tower is regenerating. Regeneration, sometimes referred to as purging, is the process by which moisture accumulated during the "on line" cycle is stripped away during the "off line" cycle. As low pressure dry purge air flows gently through the regenerating bed, it attracts the moisture that had accumulated on the surface of the desiccant during the drying cycle and exhausts that moisture laden air to atmosphere.

Features & Benefits of Parker PTW Series Air Dryers:

• Mounting: structural steel base

• Mounting: 1/2" | 3/4" | 1" | 1-1/2"| 2"

• Primary Voltage: 120V/1ph/60Hz

• Flow SCFM: 25 to 800

• Flow m³/min: .70 to 22.65

• Approximate Purge: 15%

• Maximum inlet or ambient air temperature: 120°F or 49°C

• Maximum Pressure: 150 psig or 10.5 bar

• Minimum Pressure: 50 psig or 3.5 bar

• Certifications NEMA 4; All NEMA classifications available as options

• Dew point Range: -40 to -100°F or -40 to -70°C

• Features Particulate and Coalescing pre-filters. After-filter included; solid state controller; CycleLoc™ demand control; variable cycle control (models PTW75 - PTW800 SCFM); purge flow indicator; purge flow regulator (models PTW75 -TW800 SCFM) repressurization circuit (models PTW75 - PTW800 SCFM) NEMA 4 controls; 150 psig design standard; moisture indicator (models PTW75 - PTW800 SCFM)

• Weight: 156 to 2120lbs or 71 to 962kg

• Options/accessories DDS Light / DDS (dew point dependent switching); 4-20 mA output; all NEMA classifications pressure to 1,000 PSIG; high humidity alarm; fail to switch alarm; electronic drain systems; contacts for remote alarms; NEMA 4 controls

Sizing and Model Selection

To ensure quoted air purity performance is met, a compressed air dryer must be sized correctly for minimum operating pressure, maximum inlet temperature and maximum inlet flow rate using the correction factors found in the Product Information Sheet.

For more information or a detailed discussion about your specific requirements please contact us at 727-835-0649 or Toll Free at 800-761-4298.

(Scroll right on mobile to see entire chart on mobile devices)

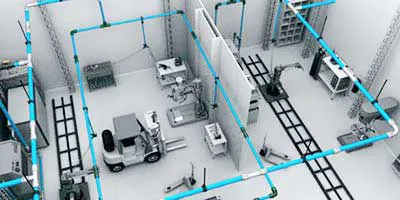

Also Available from mdi: Parker Transair Aluminum Pipe and Fittings for Compressed Air

Transair aluminum pipe is the ideal system for compressed air, vacuum, and inert gas applications. It offers significant savings on installation, maintenance and operating costs when compared to traditional compressed air piping systems. Its removable and interchangeable components allow users to easily modify production layouts or execute process changes within minutes. It's the only product with true push-to-connect fittings, eliminating the need to thread, solder or glue pipe. Its unique sealing technology guarantees Transair to be leak-free.

Continue...

Click for Larger View

Click for Larger View