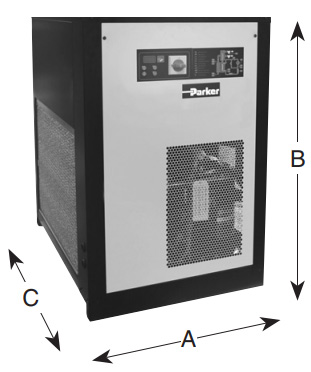

PRD 200-2400 Series Refrigeration Air Dryers

PRD 200-2400 Series refrigeration air dryers are ideal for general purpose oil free pneumatic air treatment applications. They typically provide pressure dew points of 35°F (1.7°C) to 50°F (10°C) pressure dew point (pdp). Refrigeration air dryers work by cooling the air, so are limited to positive pressure dew point ratings to prevent freezing of the condensed liquid. Refrigeration dryers use a set of heat exchangers or a single heat exchanger (with chambers) first to pre-cool the air; second to refrigerate the air to condense out moisture vapor; and last to re-heat the air to prevent pipe sweating downstream particularly in humid conditions.

Dewpoints of 38°F to 50°F are suitable for many indoor applications where general removal of water and some vapor is suitable for the end user's process.

Call us TODAY at 727-835-0649 or

Toll Free at 800-761-4298

Get A Free Quote!

Non-Cycling (Direct Expansion) dryers are a type of dryer where the compressed air and the refrigerant come into direct contact via the heat exchanger. While reliable and simple to use, they generally require that the unit continues to run regardless of actual compressed air flow through the dryer. Cycling dryers that utilize a thermal mass as the means to absorb the heat from the compressed air. By chilling a thermal mass, a refrigerant compressor may turn off in times of low demand thereby saving energy by shutting off the refrigerant compressor.

Features of Parker PRD 200-2400 Series Air Dryers:

• Optimum dewpoint levels for highest system performance

• Advanced patented design solutions

• High reliability, easy to use and maintain

• Unique 4-in-1 SmartPack heat exchanger

• Integral drain

• Extremely low pressure drop design

• SmartControl energy saving function

• Excellent dewpoint performances

• Advanced compliant scroll compressor

Sizing and Model Selection

To ensure quoted air purity performance is met, a compressed air dryer must be sized correctly for minimum operating pressure, maximum inlet temperature and maximum inlet flow rate using the Product Information Sheet.

For more information or a detailed discussion about your specific requirements please contact us at 727-835-0649 or Toll Free at 800-761-4298.

*Scroll to the right to see entire chart.

*Scroll to the right to see entire chart.

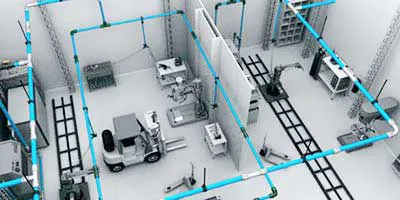

Also Available from mdi: Parker Transair Aluminum Pipe and Fittings for Compressed Air

Transair aluminum pipe is the ideal system for compressed air, vacuum, and inert gas applications. It offers significant savings on installation, maintenance and operating costs when compared to traditional compressed air piping systems. Its removable and interchangeable components allow users to easily modify production layouts or execute process changes within minutes. It's the only product with true push-to-connect fittings, eliminating the need to thread, solder or glue pipe. Its unique sealing technology guarantees Transair to be leak-free.

Continue...

Click for Larger View

Click for Larger View