NextGen TW Series Heatless Desiccant Air Dryers

Parker NextGen TW Series Heatless Desiccant Air Dryers remove water vapor from compressed air through a process known as Pressure Swing Adsorption. A standard pressure dewpoint of -40°F (-40°C) is attained by directing the flow of saturated compressed air over a bed of desiccant. The desiccant bed is regenerated by using dry purge air from the system.

Call us TODAY at 727-835-0649 or

Toll Free at 800-761-4298

Get A Free Quote!

The NextGen TW Series is the simplest desiccant air dryer in our offering, the dryer uses heatless pressure swing adsorption for drying the compressed air to -40°F PDP. The pressure swings between a left and a right tower typically on a cycle of 5 to 10 minutes. During regeneration, a percentage of the dry compressed air is used for purge, this helps regenerate the fully adsorbed desiccant.

Features & Benefits of Parker NextGen TW Series Air Dryers:

Basic Controller

• Allen Bradley® PLC

• Compressor demand via external dry contact (CycleLoc®)

• Selectable cycle settings

• Manual Stepping

PowerLoc® Energy Management System

Energy savings of up to 80% can be achieved with the proven PowerLoc® energy management system. Regeneration requirements are dependent on flow, pressure and temperature. The PowerLoc® system allows the cost of drying compressed air to be matched exactly to your plant conditions. PowerLoc® controls the drying cycle by continuously reacting to the loading under which the dryer is operating and minimizes the energy input required. As dryers rarely operate at full rated capacity all of the time (eg. during shift work and periods of low demand), this energy management system can provide considerable savings.

Sizing and Model Selection

To ensure quoted air purity performance is met, a compressed air dryer must be sized correctly for minimum operating pressure, maximum inlet temperature and maximum inlet flow rate using the Product Information Sheet

For more information or a detailed discussion about your specific requirements please contact us at 727-835-0649 or Toll Free at 800-761-4298.

How to Order

11.Basic controller switches off timer based settings, Basic Plus controller is equipped with a dewpoint probe, Advanced controller includes dewpoint probe, inlet & outlet pressure sensors, inlet temperature sensors & is equipped with IoT, refer to the product information sheet for additional controller information.

*Scroll to the right to see entire chart.

• Above information should be used as a guideline. Flows are at 100 psig inlet pressure, 100°F (38°C) inlet temperature and 100°F (38°C) ambient temperature. For specific applications, please consult an mdi representative.

• Weight includes desiccant (shipped loose Models TW2000 and up).

• Pressure relief valve variance +/- 10%.

• 120V/1Ph/60Hz Standard Electrical Supply for all TW series dryers

*Scroll to the right to see entire chart.

• Filters shown on Models TW0055—TW3000 are with Package F

Correction Factors

To obtain dryer capacity at new conditions, multiply nominal capacity x C1 x C2.*Scroll to the right to see entire chart.

*Scroll to the right to see entire chart.

*Scroll to the right to see entire chart.

Notes:

1. Dimensions shown on Models TW0055—TW3000 are with Package F.

2. Weight includes desiccant (shipped loose Models TW2000 and up).

3. Pressure relief valve variance +/- 10%. TW0055-1500 pressure relief valve set at 165 psig. TW2000-3000 pressure relief valve set at 150 psig.

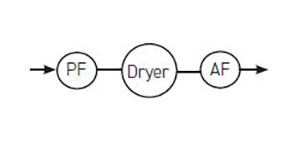

Filter Package Schematic

(Optional for TW0100 & Larger)

Includes dryer with factory installed dual selectable pre and after-filters with system bypass.

(Standard on all models)

Includes dryer with factory installed pre-filter and after-filter.

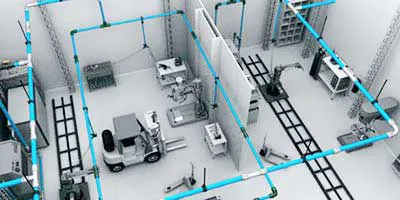

Also Available from mdi: Parker Transair Aluminum Pipe and Fittings for Compressed Air

Transair aluminum pipe is the ideal system for compressed air, vacuum, and inert gas applications. It offers significant savings on installation, maintenance and operating costs when compared to traditional compressed air piping systems. Its removable and interchangeable components allow users to easily modify production layouts or execute process changes within minutes. It's the only product with true push-to-connect fittings, eliminating the need to thread, solder or glue pipe. Its unique sealing technology guarantees Transair to be leak-free.

Continue...

Click for Larger View

Click for Larger View