Maxi PCO2 CO2 Purifiers

PCO2 CO2 Purifiers from Parker Domnick Hunter offer a comprehensive solution to preserve and guarantee the quality of gaseous carbon dioxide used in sparkling beverage bottling. Using multi-layer gas polishing technology, the PCO2 CO2 Purifiers offer plant scale protection.

Operating as a vapor polisher to remove a wide range of potential carbon dioxide impurities, the system guarantees the gas quality so it remains within industry and company guidelines, preventing detrimental consequences to the finished end beverage, producers reputation and their bottom-line.

Call us TODAY at 727-835-0649 or

Toll Free at 800-761-4298

Get A Free Quote!

PCO2 Carbon Dioxide Quality Incident Protection Systems

from Parker Domnick Hunter offer a comprehensive solution

to preserve and guarantee the quality of gaseous carbon

dioxide used in sparkling beverage bottling.

Operating as a Quality Incident Protection removing a wide

range of potential carbon dioxide impurities, the system

guarantees the gas quality so it remains within industry and

company guidelines, preventing detrimental consequences

to the finished end beverage, producers reputation and their

bottom-line.

PCO2 is the beverage industry preferred choice and is

installed in over 150 countries worldwide.

Features & Benefits of Parker Domnick Hunter Maxi PCO2 CO2 Purifiers:

• Comprehensive 5 stage polishing technology with optional 6th stage validated sterile gas filter • Simple installation

• Compact design

• Low maintenance

• Low pressure drop

• Meets ISO9001:2000 standards

• Materials of construction independent verifications to comply with FDA Code of Federal Regulations title 21 CFR

• Carbon dioxide quality guaranteed

• Protection against impurities known to create beverage flavor defects

• Ensures carbon dioxide meets industry and company specifications and guidelines

Sizing and Selection

To ensure quoted CO2 purity performance is met, a CO2 Purifier must be sized correctly for minimum operating pressure, maximum inlet temperature and maximum inlet flow rate using the Product Information Sheet.

For more information or a detailed discussion about your specific requirements please contact us at 727-835-0649 or Toll Free at 800-761-4298.

Dimensions and weight

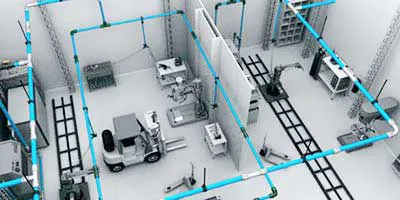

Also Available from mdi: Parker Transair Aluminum Pipe and Fittings for Compressed Air

Transair aluminum pipe is the ideal system for compressed air, vacuum, and inert gas applications. It offers significant savings on installation, maintenance and operating costs when compared to traditional compressed air piping systems. Its removable and interchangeable components allow users to easily modify production layouts or execute process changes within minutes. It's the only product with true push-to-connect fittings, eliminating the need to thread, solder or glue pipe. Its unique sealing technology guarantees Transair to be leak-free.

Continue...

Click for Larger View

Click for Larger View