Parker DRD Series Refrigeration Air Dryers

The DRD Series Dual Mode Energy Saving Refrigerated Air Dryers are designed to minimize the use of compressed air and electricity in their operation, and also to significantly reduce the operational costs of the compressor by minimizing pressure loss.

Costly contamination problems can be avoided by installing a dual mode DRD Series refrigerated dryer (ranging from 200 - 3000 scfm), with dual mode energy saving function (cycling/non-cycling) on models DRD325-DRD3000.

Call us TODAY at 727-835-0649 or

Toll Free at 800-761-4298

Get A Free Quote!

The importance of compressed air as a provider of energy for modern industrial processes is widely known. What is often overlooked is the need to provide quality treatment for this air. In fact, the air entering the system contains moisture which, when cooled, will turn into water, causing extensive damage not only to the compressed air network, but also to the finished product.

Our 4-in-1 heat exchanger offers minimal pressure drops and class leading performance, and significantly increases the efficiency of the whole compressed air treatment process. The innovative dual mode function automatically and continuously adjusts dryer operation to the effective working conditions, minimizing operating costs and maximizing performances. Compressed air purification equipment must deliver uncompromising performance and reliability while providing the right balance of air quality with the lowest cost of operation. Many manufacturers offer products for the filtration and purification of contaminated compressed air, which are often selected only upon their initial purchase cost, with little or no regard for the air quality they provide, the cost of operation throughout their life or their environmental impact. When purchasing purification equipment, delivered air quality, the overall cost of ownership and the equipment's environmental impact must always be considered.

The Parker DRD Series Dual Mode Energy Saving Refrigerated Air Dryers are the most energy efficient air dryer on the market, under all operating conditions. DRD Series compliant scroll compressors (DRD400 – DRD3000) lead the market with the lowest full-load power consumption due to its oversized heat exchanger, compliant scroll compressors, R407C environmentally friendly refrigerant and direct operation, avoiding the increased energy consumption of thermal mass-type dryers. It consumes less energy at full load and saves more energy at partial loads. Electrical consumption usually accounts for around 50% of the air dryer's total cost over a five-year period.

Features of Parker DRD Series Air Dryers:

• Optimum dewpoint levels for highest system performance

• Advanced patented design solutions

• Unique 4-in-1 SmartPack heat exchanger

• High reliability, easy to use and maintain

• Environmental, lowest real operating costs

• Dual mode integrated energy saving no loss level drain with back up timer drain with alarm (DRD325 - DRD3000)

• Extremely low pressure drop design

• Crankcase heater

• SmartControl energy saving function

• Advanced scroll compressor with Phase Monitor (400 scfm and up)

• Oversized condenser to operate in ambient to 122˚F (50˚C) with pre-filter

• 3rd party performance verified by CAGI

• ETL listed CRN registered complete unit (except Alberta)

• Dryers manufactured in facility certified to ISO9001, ISO14001, and ISO18001

Sizing and Model Selection

To ensure quoted air purity performance is met, a compressed air dryer must be sized correctly for minimum operating pressure, maximum inlet temperature and maximum inlet flow rate using the Product Information Sheet.

For more information or a detailed discussion about your specific requirements please contact us at 727-835-0649 or Toll Free at 800-761-4298.

*Scroll to the right to see entire chart.

*Scroll to the right to see entire chart.

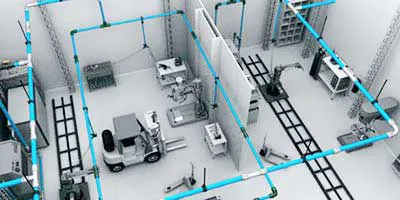

Also Available from mdi: Parker Transair Aluminum Pipe and Fittings for Compressed Air

Transair aluminum pipe is the ideal system for compressed air, vacuum, and inert gas applications. It offers significant savings on installation, maintenance and operating costs when compared to traditional compressed air piping systems. Its removable and interchangeable components allow users to easily modify production layouts or execute process changes within minutes. It's the only product with true push-to-connect fittings, eliminating the need to thread, solder or glue pipe. Its unique sealing technology guarantees Transair to be leak-free.

Continue...

Click for Larger View

Click for Larger View